Rapid Prototype Composite Tooling Using CFOAM® Carbon Foam

IT IS AN INEXPENSIVE PROCESS THAT CAN BE MANUFACTURED QUICKLY.

INTRODUCTION

As the world moves faster and parts are developed via computer aided design, the old methods of building masters (plugs) and pulling parts has become too slow and costly. Designers want to go from a CAD file to a composite part as fast as possible.

At CFOAM LLC, there has been a breakthrough in the development of inexpensive, off-the-shelf coatings providing dimensionally stable, low coefficient of thermal expansion (CTE), large (and small) rapid prototypes of carbon fiber reinforced plastics.

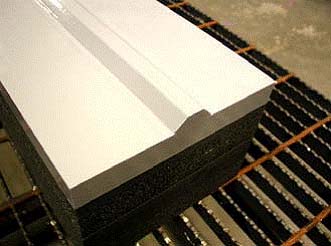

Composite tooling surface primer being sanded.

RAPID PROTOTYPE COMPOSITE TOOLING USING CFOAM® CARBON FOAM

CFOAM LLC is currently developing several processes to apply tooling surfaces to CFOAM carbon foam that are suited for prototype tools designed to make less than ten parts. It is an inexpensive process that can be manufactured quickly.

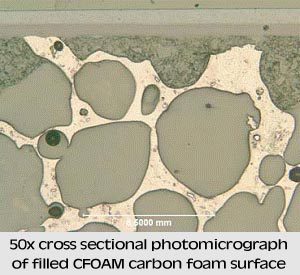

The “rapid prototype” surfacing concept begins with the application of a filler material to the top layer of the foam. The filler material has high use temperatures, suitable compressive strengths, and is easily machined or sanded. The purpose of the filler material is to fill the CFOAM® pore structure in order to create the base for a tool surface that will maintain vacuum integrity during vacuum bagging on the surface.

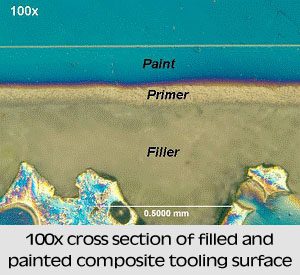

High-temperature epoxy paint is then applied to the filled foam surface in a carefully controlled manner in order to manage the final tolerance that takes into account the paint thickness. This system can be seen in the photomicrographs below.

Steps in Making a Rapid Prototype Tool Using CFOAM® Carbon Foam

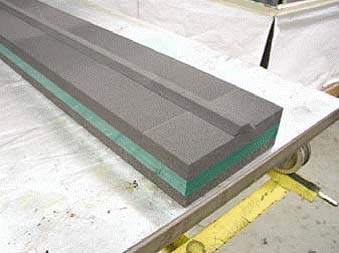

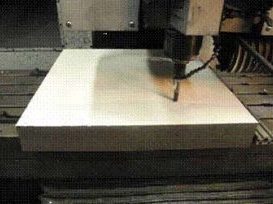

1. BLOCK AND MACHINE: First, CFOAM® panels are bonded together and machined to within 0.004″ of the desired final geometry of the tool.

2. FILL AND CURE: The filler coat is then applied to the surface of the machined foam with a squeegee and adds no measurable thickness when applied and prepared properly. The picture below shows a tool that has been filled. An oven cure in excess of 350°F is typically performed. A second coating of filler materials could be applied and oven cured if required.

Another optional process for applying a different filler material is to apply it very liberally over the entire surface of the machined tool, cure it at room temperature within an hour while the tool is on the mill, and then re-machining the tool to the finish dimensions. This eliminates hand work and the filler provides a very hard surface.

3. PRIMER COATING: After the filler material has been completely smoothed, consistent with the CFOAM® carbon foam surface by hand or via machining, a primer coating is applied by either spraying or rolling. The primer used is typically part of a two part epoxy paint that has use temperature of 400°F (204°C). The primer coating fills any remaining porosity in the filled CFOAM surface.

After the primer coat is applied, the surface is ready for the second coat of the two part epoxy paint.

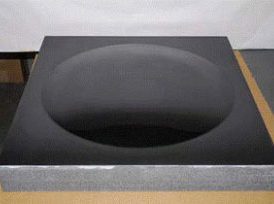

Below are two examples of completed rapid prototype tools with both coats of the two part epoxy paint system. The tool on the left shows the masking paper on the edges. The paint system adds approximately 0.004” to the surface of the tool.

To date, the rapid prototype tooling surfaces used have been used to successfully cure composite parts when the tool was vacuum bagged to a flat table, or the entire tool was envelope bagged.