Carbon Foam Fireproof Composite Core

CFOAM® CARBON FOAM HAS THE BEST FIRE, SMOKE, AND TOXICITY PROPERTIES OF ANY LIGHTWEIGHT COMPOSITE CORE MATERIAL ON THE MARKET TODAY.

CFOAM® carbon foam has the best fire, smoke, and toxicity properties of any lightweight composite core material on the market today, including other carbon foams made from polymer and pitch based precursors. Because of these properties, CFOAM® carbon foam has application in a broad range of markets, including marine, automotive, commercial aerospace, industrial, commercial, and residential building, transportation, and others.

FIRE, SMOKE, & TOXICITY (FS&T) PROPERTIES OF CFOAM® CARBON FOAM MATERIALS

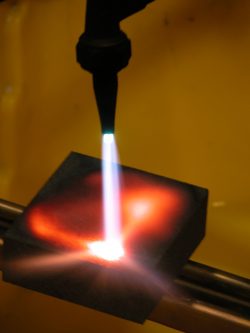

The following data is presented in order to give an overview of CFOAM LLC work in fire testing characterization of carbon foams. CFOAM® carbon foam exhibits tremendous fire properties, as exemplified in the figure that shows it being exposed to a 1650°C acetylene torch. CFOAM® carbon foam fire properties are well understood and the material has undergone almost all key fire tests. CFOAM® carbon foam will not support combustion because it is made from inorganic carbon, which is one of the best materials available in high-temperature applications, such as those experienced during fires.

CFOAM® carbon foam is capable of meeting the “non-combustible” standard when tested in accordance with ISO 1182 as directed by the U.S. Coast Guard and the International Maritime Organization (IMO), which meets Underwriter Requirements for commercial and maritime applications. ISO-1182 tests materials in a 750°C environment for combustibility with three metrics for passing: combustibility, mass loss, and temperature rise. Unlike CFOAM® carbon foam, polymer based carbon foams do not pass non-combustibility tests and are not suitable for many marine applications.

CFOAM® carbon foam has also been tested in accordance with ASTM E1354, Cone Calorimeter. Cone Calorimeter is a test for composite material systems and exposes materials to successive heat fluxes from 25-100 kW/m2. After successive heat fluxes, CFOAM® carbon foam underwent no ignition, released no heat, and generated no smoke, as seen in the following table.

Please view our video of CFOAM® carbon foam undergoing ISO 1182 testing.

ASTM E 1354 cone calorimeter test results with CFOAM® carbon foam

| Heat Flux, kW/m2 | ||||

|---|---|---|---|---|

| 25 | 50 | 75 | 100 | |

| Time to Ignition, seconds | NI | NI | NI | NI |

| Peak Heat Release Time, kW/m2 | NI | NI | NI | NI |

| Average Heat Release Rate, 3 min, kW/m2 | NI | NI | NI | NI |

| Average Heat Release Rate, 5 min, kw/m2 | NI | NI | NI | NI |

| Average Heat of Combustion, MJ/kg | NI | NI | NI | NI |

| Average Specific Extinction Area, m2/kg | NI | NI | NI | NI |

| Peak CO, concentration, ppm | NI | NI | NI | NI |

| Total Heat Released, MJ/m2 | NI | NI | NI | NI |

| Comments (NI=No Ignition) | NI after 1200 sec | NI after 1800 sec | NI after 1200 sec | NI after 1200 sec |

CFOAM® carbon foam also passes ASTM E 162 Low Flame Spread. It has received the highest rating possible with a flame spread index of 1.

FIRE, SMOKE, & TOXICITY (FS&T) PROPERTIES OF CFOAM® CARBON FOAM MATERIALS

CFOAM® carbon foam is ideal for fireblock applications in confined spaces such as ships, trains, or airplanes that have strict requirements to stop the spread of fire should one arise. CFOAM® carbon foam firewalls will contain fires that have been tested for ASTM E 119 & UL1709 fire scenarios. CFOAM® carbon foam also provides acoustic absorption, and is well suited for fireproof walls of equipment enclosures in buildings, ships, chemical plants, and others. A list of possible applications for CFOAM® carbon foam fire-resistant core materials is found below. Touchstone has years of experience designing CFOAM® carbon foam fire block wall systems and would be pleased to assist you in solving your fire block problems with CFOAM® carbon foams.

Fireproof Composite Foam Core Applications

Marine

- Commercial ship joiner panels

- Commercial ship equipment enclosures

- Military ship joiner panels

- Military ship equipment enclosures

Industrial

- Off shore platform walls and dividers

- Petroleum refineries & chemical plant equipment enclosures

- Power plant non-structural walls and dividers

- Manufacturing plant equipment enclosures

Commercial & Residential Construction

- Fire proof doors

- Fire resistant pre-fabricated walls and dividers

- Fire proof safe room cores

Transportation

- Passenger rail cars

- Subway cars

- Campers and recreational vehicles

- Automotive firewalls and floor boards

Aerospace

- Commercial aircraft fire resistant bulkheads

- Commercial airplane lightweight firewalls